|

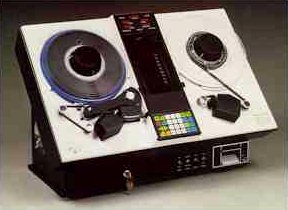

Athana International The Analyzer It Sets The Standard! |

|

Athana International The Analyzer It Sets The Standard! |

DESCRIPTION:

The Analyzer is a simple to use, microprocessor controlled complete tape management system. Our advanced microprocessor design and T.A.M.E.S. software automatically handle all critical phases of operation, including tape control, error detection and error reporting . . .with consistent accuracy.

For all of it's sophistication, the Analyzer is rugged and dependable. The table top console features straight forward, easy to use controls and operating sequences. It enables the operator to readily perform such desireable functions as intensive cleaning over a questionable section of tape, stopping on individual errors, plus detecting and identifying multi track errors. The Analyzer also provides variable length header protect as well as a hard copy printout of a tape profile.

The outstanding features of the Analyzer include a vacuum column for maximum tape protection, lifetime guaranteed rotary blades for efficient cleaning, self seating hubs, adjustable threshold levels, and machine self-diagnostics.

"State of the art" is a greatly overused expression, but not when it comes to describing the Analyzer. It is truly the quality standard for the entire industry.

What does this mean in terms of actual user benefits? Microprocessor control, for instance provides high speed computer tape analysis, and test results like error identification by track. Track error identification utilizes a Athana software program that analyzes the tape in 1560 Bit blocks (a group code record), identifies error locations on the tape as well as which tracks are affected. It also reports how many write/skips per foot of tape will be required on your drive. These benefits just simply aren't available on any other machine.

Our exclusive Tape Analysis and Management Evaluation System (T.A.M.E.S.)TM removes potential operator error from the library control function. T.A.M.E.S. reviews every tape tested against preprogrammed criteria selected by the user, and determines whether the tested tape is to be used as file tape, production tape, repaired or discarded. Disposition instructions are printed out for the operator. . . no independent judgement is required!

The Analyzer can duplicate the operation of an actual tape drive and provide error detection exactly as in GCR format (6250BPI). Variable testing thresholds permit testing at ANSl new tape specifications or at tape drive specifications (write/ skip) or any operator selected threshold. Our power packer arm system guarantees perfect tape packing and rewinding for long term, error free tape performance. If a user needs immediate operations assistance, help is only a button away. The 'user assist' key prints out—step by step—operator instructions from internal memory. Once the tape has been processed, a high speed dot matrix printer provides a permanent hard copy record. For security, important test function settings are located behind a locked panel so operators cannot arbitrarily alter critical testing specifications.

The list of benefits goes on and on. We haven't mentioned the convenience of vacuum grid cleaning and self sharpening rotary blades that eliminate the need for cleaning supplies or a host of other features and options that make the Analyzer the leader in total tape management. You have to try the Analyzer to believe it.

| FEATURES |

| The Analyzer also includes the following standard features: |

|

| OPTIONS: |

|

| SPECIFICATIONS | |

Speed: |

400 IPS Rewind, 180 IPS |

Test Cycle Time: |

3.9 Minutes-Test, 2.4 Minutes-Clean |

Reel Size: |

Up to 101/2'' Dia. (1/2" Wide) |

Hubs: |

IBM Type, Quick Release, Self-Seating |

Dimensions: |

28 1/2" Wide X 19" High X 16" Deep |

Weight: |

130 Ibs. |

Power Requirements. |

|

| 115 VAC, 60

Hz, 6 1/4 Amps-(US) 240VAC, 50 Hz, 4 Amps-(Overseas) |

|